1. I could still use my stock intake manifold (which is factory), and if I ever get around to upgrading that stock manifold to an Edelbrock Pontiac Performer manifold, I can still use this fuel injection system.

2. It was half the cost of the Edelbrock Pro-Flo FI system (which is what I was going to get originally before I saw the Retrotek Speed system), a much less than the Mass Flo system for Pontiac and the FAST systems.

3. Ease of installation. For me this was a huge reason. How it worked made sense to me. I wanted it to do two things: eliminate carburetor cold starts, and get rid of a backfire pop I was having with my Demon carburetor when I mashed down on the accelerator pedal from cruise. I could never figure that out. Accelerator pump? Maybe. My Demon in general not being tuned? Maybe. But I felt that the Retrotek Speed system would eliminate my problems and wouldn't be too difficult to install.

Here's how:

The first thing you'll want to do is decide if you're going to get a new gas tank or if you're going to use your existing one. If you're getting a new one, make sure if fits under your car and that it has good ventilation. I decided to use my stock one so that's what I'll cover here.

First, jack up the rear of the car, on both sides. Next, you'll want to disconnect the rubber hoses that are in between the main fuel feed line, the return line, and the evap/emissions lines. You'll find these if you crouch beside the passenger side rear wheel, and look through to the other rear wheel:

Get the hose clamps off or really loosened first. To do this I used a 1/4 inch little socket with a Craftsman driver that has a black handle:

Get the hose clamps off or really loosened first. To do this I used a 1/4 inch little socket with a Craftsman driver that has a black handle:

You can also get the hose clamps with flathead screwdriver if you prefer.

You can also get the hose clamps with flathead screwdriver if you prefer.To get the rubber hose parts off, I used an Exacto knife. Make sure the blade is new or really sharp, and be VERY careful. Just score along the side of the rubber, and keep scoring, and then you'll be able to peel it off with your hands. Do the same for the driver's side. Next, I got a 9/16 deep socket for the taillight side fuel tank strap nuts:

Be patient with these if these are the original nuts They can be a pain but just keep working on them and they'll come out. My buddy Crazy Carl loosened them for me and he did it so fast I didn't have time to properly set up the camera, so, sorry about the above two pics being blurry! We did manage to get a good pic though in the end. :)

Be patient with these if these are the original nuts They can be a pain but just keep working on them and they'll come out. My buddy Crazy Carl loosened them for me and he did it so fast I didn't have time to properly set up the camera, so, sorry about the above two pics being blurry! We did manage to get a good pic though in the end. :)Now before you take out that last nut, either have a jack with a wide piece of wood under the fuel tank to support it so it doesn't fall, or lie on your back underneath the car with a buddy on his back right next to you, with both your arms supporting the tank when the last bolt comes out. Even though I did it the latter way, I don't recommend it. Its physically awkward working the tank out that way. Take your time and be safe.

After the last nut is out and the tank is loose but supported, you can slide the fuel tank straps down the threaded bolts. The tank will start to lower. Just keep working it out, and be mindful of any connections you may have missed, AND the fuel gauge ground and cinder wires that are on top of the fuel tank. Eventually you'll have it all the way out:

Next I had to drain the fuel out of the tank. I got a good size CLEAR (so you can see the fuel) hose from Ace Hardware. Then Carl and I set the fuel tank at a higher level; we just propped it up on my trash can.

Next I had to drain the fuel out of the tank. I got a good size CLEAR (so you can see the fuel) hose from Ace Hardware. Then Carl and I set the fuel tank at a higher level; we just propped it up on my trash can. Then I made a diagram of how I was going to drain the fuel out of the tank:

Then I made a diagram of how I was going to drain the fuel out of the tank: And then I just went by my diagram, and sucked through the hose until I saw the gasoline start to come out. Then I just put the hose into a gas container:

And then I just went by my diagram, and sucked through the hose until I saw the gasoline start to come out. Then I just put the hose into a gas container: Next I removed the fuel sending unit so that I could replace the fuel sending unit filter sock. The way you remove the fuel sending unit is to have you and a buddy set screwdrivers on the fuel sending unit "tabs" and hammer on the ends of the screwdrivers so that the fuel sending unit moves counter-clockwise:

Next I removed the fuel sending unit so that I could replace the fuel sending unit filter sock. The way you remove the fuel sending unit is to have you and a buddy set screwdrivers on the fuel sending unit "tabs" and hammer on the ends of the screwdrivers so that the fuel sending unit moves counter-clockwise: After a few hammer hits, you’ll be able to pull out the fuel sending unit and see your existing filter sock:

After a few hammer hits, you’ll be able to pull out the fuel sending unit and see your existing filter sock: To remove the sock, just pull it off (you might have to twist a little while you pull, or pull with some force):

To remove the sock, just pull it off (you might have to twist a little while you pull, or pull with some force): I ordered a replacement sock from Ames Performance. It was the 3/8” one, FM327, and it was $22 (including shipping). To install it, just push it back on; you might have to twist it a little while you push. Don’t put the fuel sending unit back in the tank just yet though if you have to clean the tank out. I had to clean mine out, and used mineral spirits from Bering’s Hardware store to do it:

I ordered a replacement sock from Ames Performance. It was the 3/8” one, FM327, and it was $22 (including shipping). To install it, just push it back on; you might have to twist it a little while you push. Don’t put the fuel sending unit back in the tank just yet though if you have to clean the tank out. I had to clean mine out, and used mineral spirits from Bering’s Hardware store to do it:

Make sure all the gas is out of the tank. Wait a few days for the remaining gas in there to evaporate. Then put in your mineral spirits, and, with a friend, keep tilting the gas tank so the mineral spirits liquid slowly swishes all around the tank, including all the corners. Then pour it out. Then add some more mineral spirits and repeat. We did this three or four times, and then poured it all out, and waited a few days to a week so that it was all evaporated. After that, we installed the fuel sending unit back into the tank.

Make sure all the gas is out of the tank. Wait a few days for the remaining gas in there to evaporate. Then put in your mineral spirits, and, with a friend, keep tilting the gas tank so the mineral spirits liquid slowly swishes all around the tank, including all the corners. Then pour it out. Then add some more mineral spirits and repeat. We did this three or four times, and then poured it all out, and waited a few days to a week so that it was all evaporated. After that, we installed the fuel sending unit back into the tank.Next it was time to put the adapter connection on the main hard tube fuel line coming from the fuel sending unit. I liked the look of stainless steel braided fuel line and always wanted to use it, so I went to Summit Racing’s website and got some, along with some other fittings I would need. The part number for the braided line I got, a -6 AN (AN stands for Army/Navy, and is a style of measurement) line, is SUM-230620, AND WAS $74. I also got 5 of these fittings: Summit part number 800106ERL ($6.25) and some assembly lube: EAR-184004ERL ($6.50). I also got this hose cutter from Summit, so that cutting the braided hose would be easy: SUM-900040, $36. Then I bought the Koul Tool, which is specifically designed to make installing stainless steel hose into AN fittings an easy job. The tool is AWESOME, and makes installing braided line actually fun.

So the adapter fitting I needed would adapt this main fuel hard line:

to the stainless steel braided hose. Thanks to a good group of guys on the Performance Years forum, they informed me that the adapter fitting I needed was Summit part number SUM-2200077 ($8).

to the stainless steel braided hose. Thanks to a good group of guys on the Performance Years forum, they informed me that the adapter fitting I needed was Summit part number SUM-2200077 ($8).

I decided I would need some AN wrenches too, so I got two of these -6 AN wrenches from Summit, pn SUM-900106 ($10 each):

I decided I would need some AN wrenches too, so I got two of these -6 AN wrenches from Summit, pn SUM-900106 ($10 each): And then I got two adjustable wrenches ($45 each) from the local speed shop Texas Performance:

And then I got two adjustable wrenches ($45 each) from the local speed shop Texas Performance:

Now in order for the Summit adapter fitting to fit onto the hard fuel line, you’ll have to cut off the flare:

Now in order for the Summit adapter fitting to fit onto the hard fuel line, you’ll have to cut off the flare: To do this, you just use a tube cutter. I got mine from Sears Hardware:

To do this, you just use a tube cutter. I got mine from Sears Hardware: To use it, just clamp it a little around the tube, and go around and around the tube, scoring it, then tightening it, scoring it some more, until the piece just cuts off:

To use it, just clamp it a little around the tube, and go around and around the tube, scoring it, then tightening it, scoring it some more, until the piece just cuts off:

Then you can file/deburr the hole with a file to smooth it out some. I used this one from Sears:

Then you can file/deburr the hole with a file to smooth it out some. I used this one from Sears: Then you take the red AN fitting, and the brass ferrule, and slide them onto the end of the main hard fuel line you just cut and deburred:

Then you take the red AN fitting, and the brass ferrule, and slide them onto the end of the main hard fuel line you just cut and deburred: Then seat the hard tube into the blue fitting, and as it's seated, move the red fitting down into the blue fitting, and screw it down all the way, tight:

Then seat the hard tube into the blue fitting, and as it's seated, move the red fitting down into the blue fitting, and screw it down all the way, tight:

Now it's time to start plumbing the fuel system. Retrotekspeed says that for cars making less than 500 horsepower, you can run a returnless system. That's what I chose to do, and I made a diagram of how the fuel system should be plumbed:

Now it's time to start plumbing the fuel system. Retrotekspeed says that for cars making less than 500 horsepower, you can run a returnless system. That's what I chose to do, and I made a diagram of how the fuel system should be plumbed: Notice the pre-filter AND the post filter (they are the same part number). I got them from Summit, and checked with Retrotek to see if they would work. Retrotek confirmed that they would, so I got two. It's pn 230101 if you want blue ones like I got, or pn 230100 if you want red ones. They're $27 each.

Notice the pre-filter AND the post filter (they are the same part number). I got them from Summit, and checked with Retrotek to see if they would work. Retrotek confirmed that they would, so I got two. It's pn 230101 if you want blue ones like I got, or pn 230100 if you want red ones. They're $27 each.Now to actually make some of the connections in my fuel system, I hard to learn how to put AN fittings onto stainless steel braided hose. Here's how I did it:

Make sure you measure what lengths of line you need to have in between all of the fittings. When you're ready to start actually cutting (and applying fittings), take the braided hose and wrap some duct tape around an end of the braided line:

Before you cut into the braided line, put the red part from this fitting:

Before you cut into the braided line, put the red part from this fitting: inside of the Koul Tool:

inside of the Koul Tool: Then put the two pieces of the Koul Tool together, and put the Koul Tool in a vise:

Then put the two pieces of the Koul Tool together, and put the Koul Tool in a vise: Then have someone hold the braided line, while you use the Summit cutting tool. Position the tool so that it will cut in the middle of the duct tape wrap, and cut:

Then have someone hold the braided line, while you use the Summit cutting tool. Position the tool so that it will cut in the middle of the duct tape wrap, and cut: Then unwrap the duct tape on the line, and very quickly insert it, twisting as you go, all the way into the Koul Tool in your vise:

Then unwrap the duct tape on the line, and very quickly insert it, twisting as you go, all the way into the Koul Tool in your vise:If you want to check how far you've inserted the braided line into the red fitting, just remove the Koul Tool from the vise, open it, and look down into the red fitting. The edge of the hose should come up to around this ridge:

When you're done it should look like this:

When you're done it should look like this: To attach the blue part that goes with the red part that is now on the hose, put the red part of the hose into a vise, with the hose going to the floor. Put some of the Earl's Assembly Lube on the blue part's threads, and use a combination of pushing down (by hand) and screwing the red and blue part together with AN wrenches and the vise:

To attach the blue part that goes with the red part that is now on the hose, put the red part of the hose into a vise, with the hose going to the floor. Put some of the Earl's Assembly Lube on the blue part's threads, and use a combination of pushing down (by hand) and screwing the red and blue part together with AN wrenches and the vise: After putting the braided lines and fittings together, I had to decide where to mount the fuel pump and my two filters, the pre-filter and the post-filter.

After putting the braided lines and fittings together, I had to decide where to mount the fuel pump and my two filters, the pre-filter and the post-filter.The Retrotekspeed installation manual says to put the fuel tank at or below the pump. I went to Ace Hardware and got these self-tapping screws to mount the fuel pump's brackets:

And here's where I decided to mount the fuel pump (notice the side of the car):

And here's where I decided to mount the fuel pump (notice the side of the car):

We noticed that the holes on the brackets were not the same size. On each bracket (there are two of them as you can see in the above pic), one hole is smaller and one is bigger. In order for my self-tapping screws to go into both holes, I had to use a drill to enlarge the smaller hole some. By the way, with self-tapping screws you DON'T have to drill a hole for the screw. Just press the tip hard into the metal and start screwing while you're pressing hard.

We noticed that the holes on the brackets were not the same size. On each bracket (there are two of them as you can see in the above pic), one hole is smaller and one is bigger. In order for my self-tapping screws to go into both holes, I had to use a drill to enlarge the smaller hole some. By the way, with self-tapping screws you DON'T have to drill a hole for the screw. Just press the tip hard into the metal and start screwing while you're pressing hard.Now that the fuel pump was mounted, I had to come up with a way to make brackets for the fuel filters so I could mount those to the car too. I went to Ace Hardware and got metal cutter scissors, Red Rubber Sheet Packing, and some Galvanized Steel Hanger Strap:

With some regular scissors (not the metal cutters), I cut a strip of the red rubber, and with the metal cutter scissors I cut a strip of the steel hanger strap. I wrapped them both around the fuel filter(s), and stuck a self-tapping screw through both of them:

With some regular scissors (not the metal cutters), I cut a strip of the red rubber, and with the metal cutter scissors I cut a strip of the steel hanger strap. I wrapped them both around the fuel filter(s), and stuck a self-tapping screw through both of them: Here are two different camera angles of where I mounted the pre-filter:

Here are two different camera angles of where I mounted the pre-filter: And here is a pic of where I mounted the post-filter:

And here is a pic of where I mounted the post-filter: Then, just connect all your fittings and braided line from the fuel sending unit to the engine bay, and don't forget to use Earl's Assembly Lube on threads. To connect the braided line to the fuel pump's nozzles I just used a hose clamp on the inlet side, and for the outlet side, my buddy BigAss Blake wrapped the base up in a ton of electrical tape because of the positive and negative electrical connections, before putting on the hose clamp. To run the braided line along the length of the car, I just zip-tied it to the original main fuel hard line. Here are some pics of the plumbing:

Then, just connect all your fittings and braided line from the fuel sending unit to the engine bay, and don't forget to use Earl's Assembly Lube on threads. To connect the braided line to the fuel pump's nozzles I just used a hose clamp on the inlet side, and for the outlet side, my buddy BigAss Blake wrapped the base up in a ton of electrical tape because of the positive and negative electrical connections, before putting on the hose clamp. To run the braided line along the length of the car, I just zip-tied it to the original main fuel hard line. Here are some pics of the plumbing:

Now you can block off the original fuel tank and return ports not being used. I used this epoxy from Ace Hardware:

Now you can block off the original fuel tank and return ports not being used. I used this epoxy from Ace Hardware: To use it, just tear some off and knead it together like dough until it changes to a darker color. Then just apply it to what you want to seal up. If your epoxy is different, just read the instructions to make sure.

To use it, just tear some off and knead it together like dough until it changes to a darker color. Then just apply it to what you want to seal up. If your epoxy is different, just read the instructions to make sure.I put my epoxy on some fuel hose pieces I cut (3/8" for the main line, and 1/4" for the others), waited for the epoxy to dry, and slid the hose onto the hard lines and secured them with hose clamps:

Next up was removing the mechanical fuel pump. I had to use a 5/8 open ended wrench for the hard line:

Next up was removing the mechanical fuel pump. I had to use a 5/8 open ended wrench for the hard line: Note that when you do this some fuel will most likely spill out. For the fuel pump bracket bolts, you need to use a combination of 1/2" sockets and 1/2" and 1/4" ratchets with extensions because the firewall-side bolt is in a pretty tight spot. just keep working at it though and it will eventually come out.

Note that when you do this some fuel will most likely spill out. For the fuel pump bracket bolts, you need to use a combination of 1/2" sockets and 1/2" and 1/4" ratchets with extensions because the firewall-side bolt is in a pretty tight spot. just keep working at it though and it will eventually come out.To replace the mechanical fuel pump, I got this blockoff plate from Kauffman Racing:

To install it, use the Ultra Black silicone and run a 1/8" bead on the block only, no gasket, and use brand new bolts (I got mine from Ace):

To install it, use the Ultra Black silicone and run a 1/8" bead on the block only, no gasket, and use brand new bolts (I got mine from Ace):

Next I had to pull one of my headers so that I could get an O2 bung welded on to it. The first thing I had to do was measure and mark where the O2 sensor would go. Its best if its standing upright, 3 to 6 inches from where the primaries meet. I decided this was a good spot:

Next I had to pull one of my headers so that I could get an O2 bung welded on to it. The first thing I had to do was measure and mark where the O2 sensor would go. Its best if its standing upright, 3 to 6 inches from where the primaries meet. I decided this was a good spot: I marked it with tape and marker and made sure I knew where to mark it (quadruple checked). Now before I could get it out, I had to remove the oil filter bracket. There are 3 bolts that hold it on and I had to use a 14mm socket. Once that was out, I unbolted the header at the collector and then unbolted the 4 header bolts from the head (these bolts were 3/8" on mine).

I marked it with tape and marker and made sure I knew where to mark it (quadruple checked). Now before I could get it out, I had to remove the oil filter bracket. There are 3 bolts that hold it on and I had to use a 14mm socket. Once that was out, I unbolted the header at the collector and then unbolted the 4 header bolts from the head (these bolts were 3/8" on mine).Once it came out, I went to a speed shop with the Retrotekspeed O2 sensor they included in the kit, and got an O2 bung. I took the sensor along to make sure it screwed in without any problems. Then I marked where I wanted the O2 bung to be for the welder, so he would know exactly where to put it:

Carl's brother works at Midas and welds O2 bungs all the time so I just gave my header and my O2 bung to Carl. Two days later, I've got a header with a welded O2 bung in it!

Carl's brother works at Midas and welds O2 bungs all the time so I just gave my header and my O2 bung to Carl. Two days later, I've got a header with a welded O2 bung in it!

Before I bolted the header back on, I went to NAPA Auto Parts and got some 10W-30 Royal Purple oil, some Peak 50/50 anti-freeze, and an oil filter:

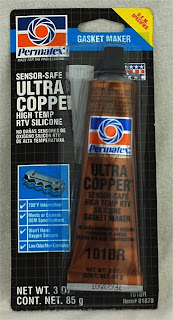

Before I bolted the header back on, I went to NAPA Auto Parts and got some 10W-30 Royal Purple oil, some Peak 50/50 anti-freeze, and an oil filter: I then bolted the oil filter bracket back on (with new bolts from Ace, of course), put the oil filter on, and bolted the header back on, using a new collector gasket, and this header gasket and Ultra Copper sealant (for the sealant, just put a bead all around the gasket ports):

I then bolted the oil filter bracket back on (with new bolts from Ace, of course), put the oil filter on, and bolted the header back on, using a new collector gasket, and this header gasket and Ultra Copper sealant (for the sealant, just put a bead all around the gasket ports):

Then it was time to make a hole in the firewall. To do this I used a 2 inch hole saw, and here are the two things I had to get from Home Depot:

Then it was time to make a hole in the firewall. To do this I used a 2 inch hole saw, and here are the two things I had to get from Home Depot: Here’s how they go together:

Here’s how they go together:

Pull back the carpet with your bare hands to expose the sheetmetal, and you’re ready to drill. When you drill, keep a steady hand, and gradually push it through the sheetmetal so that the teeth keeps scoring the sheetmetal as it rotates. Eventually, you’ll make it all the way through.

Pull back the carpet with your bare hands to expose the sheetmetal, and you’re ready to drill. When you drill, keep a steady hand, and gradually push it through the sheetmetal so that the teeth keeps scoring the sheetmetal as it rotates. Eventually, you’ll make it all the way through.I got a SealsIt grommet from Summit, which is Summit pn GS1003-20 ($18). Honestly that one was a little too big and I should have gotten a smaller one. Oh well, it’s my first time doing this stuff so of course I’ll make mistakes.

Next, just position the grommet and use self-tapping screws to secure it.

Now you can rotate the wiring harness. Connect the wiring harness to the pretty blue Retrotekspeed ECM and get in the car. Just route each sensor wire through the grommet one at a time while a friend pulls them up from the engine bay.

Set the sensors aside in the engine bay and you can now unbolt your carburetor so that the throttle body can replace it. I’m going to go through the steps of removing a carburetor in case it will help anyone.

Before unbolting the carburetor, you first need to disconnect the fuel line going to it and label every vacuum line (masking tape and a Sharpie marker are great for this). I used a screwdriver and a hammer to wedge the screwdriver into the fuel hose connected to my Demon carburetor:

This REALLY helped in getting the hoses off. My buddy Liz taught me that. :) I used rags to catch fuel that would spill out also. Next, put your hand around the black throttle cable sheath, indicated by the arrow in the pic below:

This REALLY helped in getting the hoses off. My buddy Liz taught me that. :) I used rags to catch fuel that would spill out also. Next, put your hand around the black throttle cable sheath, indicated by the arrow in the pic below: and pull on it, hard, away from the carburetor. It will pop off of it’s ball joint:

and pull on it, hard, away from the carburetor. It will pop off of it’s ball joint: Then use a ratchet, an extension, and a socket to unbolt the four bolts at each corner if necessary:

Then use a ratchet, an extension, and a socket to unbolt the four bolts at each corner if necessary: Then, simply lift up and the carb will come right off!:

Then, simply lift up and the carb will come right off!:

I covered the open intake with a trash bag until I got around to installing the throttle body:

I covered the open intake with a trash bag until I got around to installing the throttle body: to keep debris from falling into it.

to keep debris from falling into it.I wanted to replace my Quadrajet to 4150 adapter plate and just used a 7/32 Allen wrench to get the adapter plate bolts out:

I had to get to get a new ball joint for the black throttle cable sheath because the one from my Demon was too big to fit through the primary throttle lever. I got this kit from Summit since it was only $11: part number Holley 20-2. It was perfect. With new gaskets and the adapter plate on, just slide the Retrotekspeed throttle body onto the bolts, and secure it with four nuts:

I had to get to get a new ball joint for the black throttle cable sheath because the one from my Demon was too big to fit through the primary throttle lever. I got this kit from Summit since it was only $11: part number Holley 20-2. It was perfect. With new gaskets and the adapter plate on, just slide the Retrotekspeed throttle body onto the bolts, and secure it with four nuts:

Now you can finish routing the rest of the stainless steel braided fuel line (please excuse the ghetto zip ties):

Now you can finish routing the rest of the stainless steel braided fuel line (please excuse the ghetto zip ties):

Now you can connect all of the sensors. The Retrotekspeed Instruction Manual is very good instructing you on this, and it was really easy, but I’m going to add some additional info in case it might make it easier for someone. Regarding the coolant temp sensor, you might need this part from the NAPA Auto Parts store:

Now you can connect all of the sensors. The Retrotekspeed Instruction Manual is very good instructing you on this, and it was really easy, but I’m going to add some additional info in case it might make it easier for someone. Regarding the coolant temp sensor, you might need this part from the NAPA Auto Parts store:

You can put it into the passenger side head where the old coolant temp sensor was, if you want (that’s what I did). You will also need to use Blue Loctite Threadlocker 246. This was really hard to find. I finally found some from this company: http://www.rshughes.com. They had an office in Houston that had it in stock so I was in luck. My bottle was $50 (50 ml).

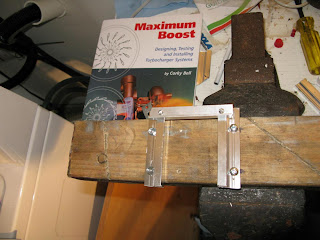

You can put it into the passenger side head where the old coolant temp sensor was, if you want (that’s what I did). You will also need to use Blue Loctite Threadlocker 246. This was really hard to find. I finally found some from this company: http://www.rshughes.com. They had an office in Houston that had it in stock so I was in luck. My bottle was $50 (50 ml).For the O2 module, I made a ghetto bracket using some parts from ACE hardware and Home Depot. The parts I got from ACE were a mirror siding and some tiny screws, and the part I got from Home Depot was a C-bar, which Crazy Carl made into an L-bar with an angle grinder. Before making the bracket, Carl used a block of wood to screw the parts against for proper measurement. Then we put the parts together and secured it to the car’s sheetmetal using self-tapping screws:

Next up was the wiring, which were only three wires! These three wires are the ignition wire, the positive fuel pump wire, and the negative fuel pump wire. Regarding the ignition wire, Retrotekspeed’s Installation Manual says that it will be labeled KEY POS. Mine wasn’t. Mine was labeled IGNITION I think (or something like that). What I did was I put a female spade connector on the end of it, and stuck it into the terminal labeled IGN. on the fuse block:

Next up was the wiring, which were only three wires! These three wires are the ignition wire, the positive fuel pump wire, and the negative fuel pump wire. Regarding the ignition wire, Retrotekspeed’s Installation Manual says that it will be labeled KEY POS. Mine wasn’t. Mine was labeled IGNITION I think (or something like that). What I did was I put a female spade connector on the end of it, and stuck it into the terminal labeled IGN. on the fuse block:

For the positive and negative battery terminals, just put those wires on the fuel pump terminals that are labeled with a plus and a minus sign. They’re on the white part and can be hard to see at first glance so here’s a pic (nevermind the white arrow pointing to the nozzle, I was using that to ask someone a question):

For the positive and negative battery terminals, just put those wires on the fuel pump terminals that are labeled with a plus and a minus sign. They’re on the white part and can be hard to see at first glance so here’s a pic (nevermind the white arrow pointing to the nozzle, I was using that to ask someone a question): Next I did an oil change and a coolant change with the oil, oil filter, and coolant I got from NAPA earlier.

Next I did an oil change and a coolant change with the oil, oil filter, and coolant I got from NAPA earlier.Now it was time to hook up the laptop to the ECM, install the Retrotekspeed software from their CD, and load a fuel maps profile:

Retrotekspeed’s manual explains how to enter in some information about your engine to load a fuel maps profile. The fuel map I used for my Pontiac 400 was RTG102-8cylHEI_NA_475tq_300tf_Performance.rgf. Once that’s done, turn the ignition key to the on position and let the fuel pump do it’s thing for a few seconds. Once you hear it whine down, start your engine! Congratulations, you’ve just converted to fuel injection. Check for leaks, and have fun!

Retrotekspeed’s manual explains how to enter in some information about your engine to load a fuel maps profile. The fuel map I used for my Pontiac 400 was RTG102-8cylHEI_NA_475tq_300tf_Performance.rgf. Once that’s done, turn the ignition key to the on position and let the fuel pump do it’s thing for a few seconds. Once you hear it whine down, start your engine! Congratulations, you’ve just converted to fuel injection. Check for leaks, and have fun!

Issues I had along the way:

Despite the embarrassment, I’ll share how I did some things wrong, and some other issues I had converting to this fuel injection system.

1. It was my first time using a tube cutter, and I just pressed the blade into the metal really hard. That was totally WRONG:

2. I DID NOT PROPERLY VENT MY TANK. I plugged up all those open ports with epoxy, remember? BIG OOPS. Retrotek told me to use the old return line I had and run a hose (I think I used a 1/4 “ hose for this) from it to above the tank to outside air. This seems to help so far.

2. I DID NOT PROPERLY VENT MY TANK. I plugged up all those open ports with epoxy, remember? BIG OOPS. Retrotek told me to use the old return line I had and run a hose (I think I used a 1/4 “ hose for this) from it to above the tank to outside air. This seems to help so far.3. The Retrotek fuel injection system is a 1:1 system, NOT a progressive linkage system. This means that when the primary throttle blades open, the secondaries need to open at the same time (as opposed to the secondaries opening later, when the engine needs extra fuel for more power). I had to get this Holley linkage from Summit Racing, part number HLY-20-122. Retrotekspeed says that they will include this style of linkage in their kits in the very near future.

4. UPGRADE NOT ONLY THE ALTERNATOR, BUT THE ALTERNATOR WIRING ALSO. I upgraded my 60 amp AC Delco alternator to a 140 amp one, but I used the stock alternator wiring. The BATT. TERMINAL wire (that goes from the back of the alternator) burned up and I had to solder connect a new, bigger wire, and I had to run a huge 2 gauge battery wire between the alternator and the battery:

I will show you how to uninstall and reinstall the alternator in a later post.

I will show you how to uninstall and reinstall the alternator in a later post.5. Leaks. I had three leaks (from AN fittings) at the back of the car near the tank, one of which was the compression fitting. My buds Hercules Hodges and Bigass Blake tightened them up for me since I was on medical leave at the time. The third leak was here:

Just tighten that with an adjustable AN wrench and it should be OK.

Just tighten that with an adjustable AN wrench and it should be OK.6. The secondary throttle return spring needed to be tightened. The gurus at the Pro-touring forums helped figure this one out (thanks again, guys). The secondaries didn’t come down to idle, so my better half and I grabbed some wrenches and pliers and tightened it, wrapping the end of the spring wire around black rod. We were able to wrap it around the black rod not once, but TWICE:

7. Bolt and wingnut for the air cleaner. I couldn’t use the air cleaner bolt I had for the Demon because it was too big. I went to ACE Hardware and got a 14-20 bolt, a wingnut that fit it, and a washer. When I got home, I just measured the length the bolt needed to be (if it’s too long the hood won’t shut), marked it with a Sharpie, and used an angle grinder with a cutoff wheel to cut it. I just went slow with the tool, scoring down the bolt, until it cut in two:

7. Bolt and wingnut for the air cleaner. I couldn’t use the air cleaner bolt I had for the Demon because it was too big. I went to ACE Hardware and got a 14-20 bolt, a wingnut that fit it, and a washer. When I got home, I just measured the length the bolt needed to be (if it’s too long the hood won’t shut), marked it with a Sharpie, and used an angle grinder with a cutoff wheel to cut it. I just went slow with the tool, scoring down the bolt, until it cut in two:

Well, that’s it so far! Drive the car around or have someone else drive it and see if you can tune it by changing the AF Target numbers on the laptop and Retrotekspeed’s software (refer to the manual for the specifics on how to do this). The system will adjust itself and supposedly even recognizes your driving style after a while.

Well, that’s it so far! Drive the car around or have someone else drive it and see if you can tune it by changing the AF Target numbers on the laptop and Retrotekspeed’s software (refer to the manual for the specifics on how to do this). The system will adjust itself and supposedly even recognizes your driving style after a while.As a final note, I want to comment on the great customer service Retrotekspeed has given me. I called them a ton and even though they were busy, Mark, Cody, and the rest of the team were all really cool to talk to, extremely helpful and patient, and had positive attitudes. This type of service is becoming more rare these days and I believe in giving credit where credit is due.

The Retrotekspeed system has been doing well. I drove the car out of town, and in Houston rush hour traffic, and it was great! And that's without the car even being tuned (just running off of the base profile)! It will be a lot of fun tuning it and getting the car the way I want. I'm also going to run a return line soon.

If anyone who reads this has any questions or comments, feel free to send me an email at zigzautonotes [at] gmail [dot] com, or just hit me up on the forums. :)

Next up, be on the lookout for blog posts on upgrading a fourth gen v6 Camaro (my college car) to an LS1 v8!

Next up, be on the lookout for blog posts on upgrading a fourth gen v6 Camaro (my college car) to an LS1 v8!